Dr. N.

In the last article we have seen the innovations brought about by the use of silicon in luxury mechanical watches. Today we will discover that the metal in the spirals still has a future, indeed, that it is probably the most suitable material for making durable and precise watches.

There are two manufacturers on which we focus in this article: Rolex and the Swatch group. Both these watchmaking companies have chosen to invest in metal alloy spirals: let's find out why.

Why a metal spiral?

Silicon spirals today are a popular choice for many watchmakers. The reasons are immediately evident, as we have been able to explain: silicon is insensitive to sudden changes in temperature and, above all, to magnetic fields, which entail considerable difficulties for the daily functioning of a mechanical watch.

However, silicon spirals also have flaws. In addition to the fragility, which entails the risk of breakage in the event of careless manipulation of the spiral by a careless watchmaker, there is the unknown of duration over time. In fact, silicon may no longer be produced in the future, furthermore, not having silicon spirals that are at least a few decades old prevents us from knowing how well this material withstands the passage of time.

This is why two great companies like Rolex and the Swatch Group wanted to invest in the new generation metal alloy spirals, despite having silicon technology available and having used it in their timepieces - Rolex with Tudor, Swatch with Omega -.

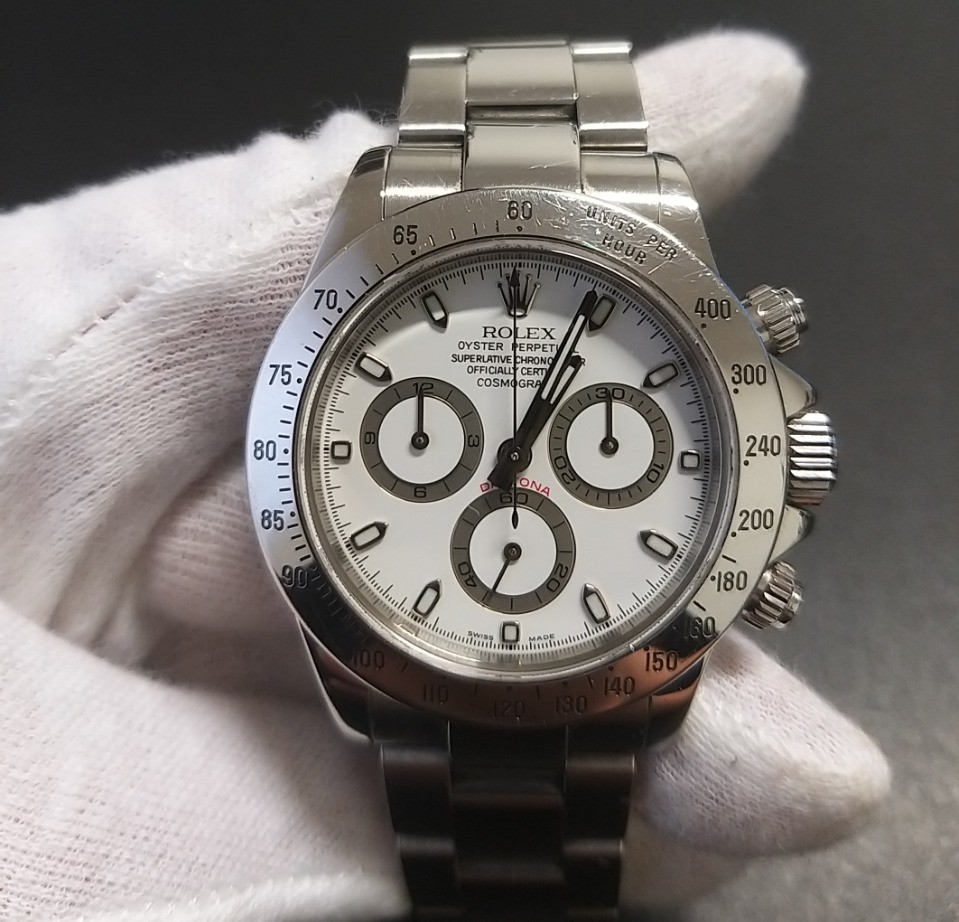

The Parachrom hairspring from Rolex

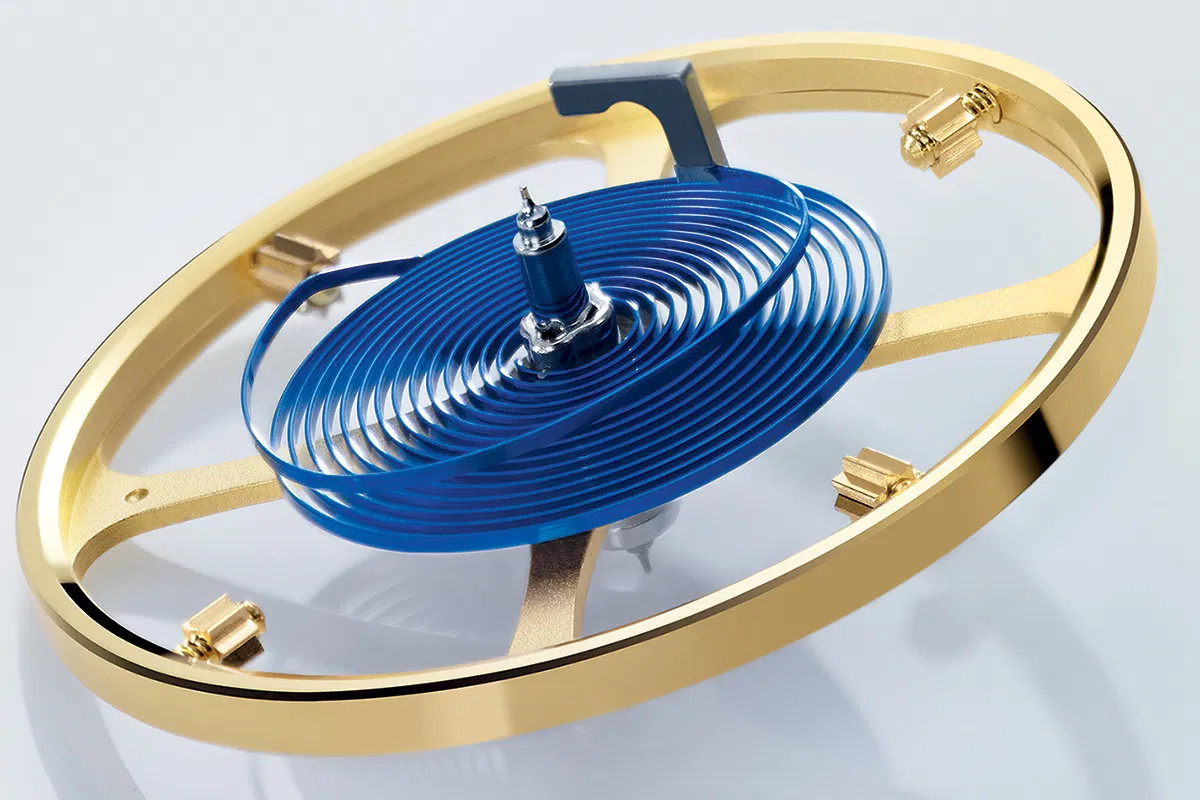

Rolex has chosen to invest in the creation of a metal alloy hairspring highly resistant to magnetic fields, after experimenting with silicon technology in the Tudor range. The result of Rolex's investments is the famous blue Parachrome hairspring, which for some years has been gradually replacing traditional spirals in the Rolex range as the various models are updated.

Rolex's blue Parachrom hairspring is made of an alloy of niobium, zirconium and oxygen fused in an extremely high vacuum. The manufacturing process leads to the formation of a metallic blue surface patina, which gives an immediate recognition to this spiral.

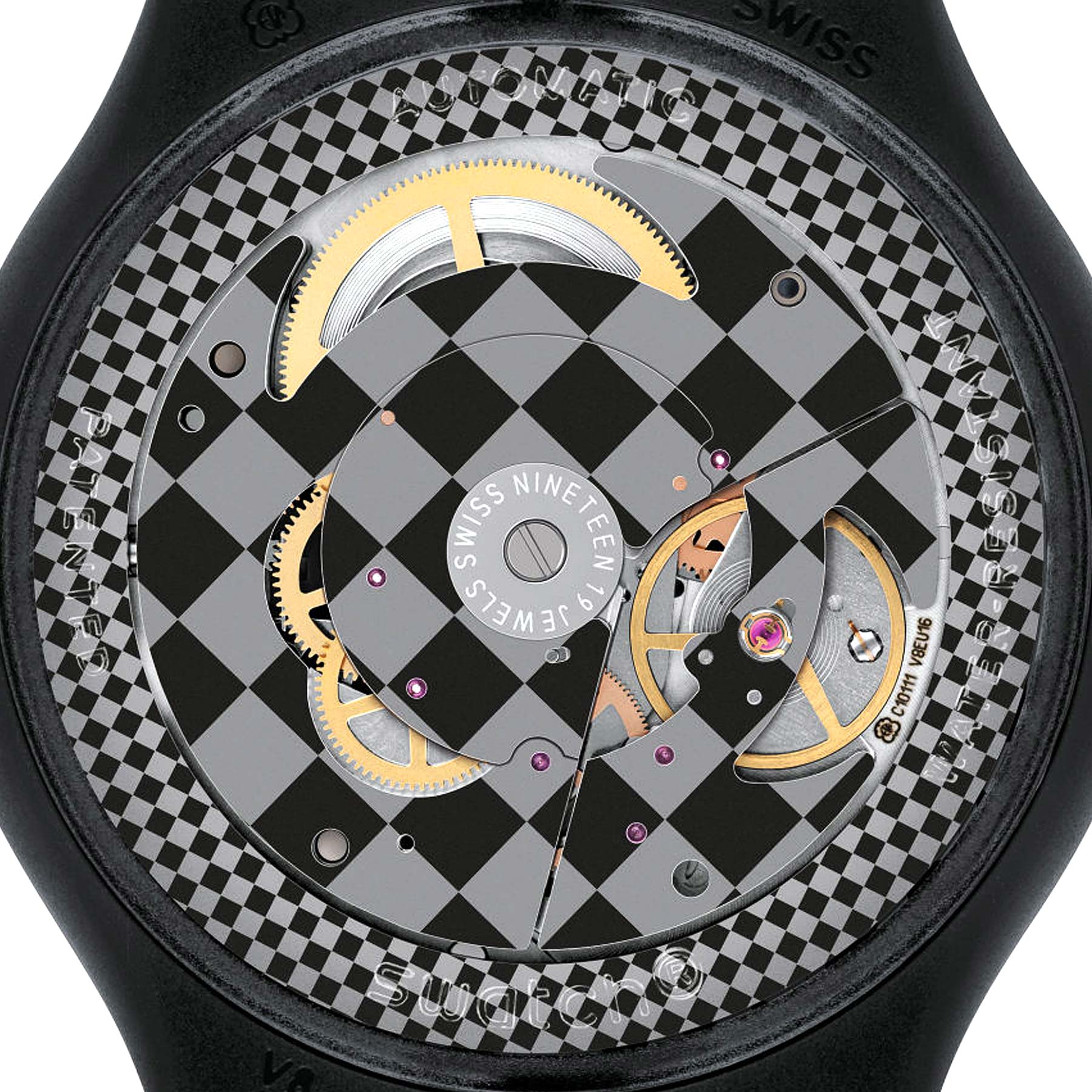

The Nivachron hairspring by Swatch and Audemars Piguet

Il Swatch group, which includes leading watch companies such as Breguet, Omega, Blancpain, Longines, Hamilton, it has always stood out for its ability to innovate. With Omega, silicon spirals have been used, but this does not mean that the first world watchmaking group has chosen to be satisfied. Joining forces with Audemars Piguet, a titanium-based spiral has developed, probably the most suitable material for the purpose due to its poor sensitivity to magnetic fields and sudden changes in temperature. However, titanium has a defect, which so far has prevented its use for the balance wheel spirals: it is very energy-intensive. The contraction and expansion of a titanium spring absorbs a lot of energy, which is a serious problem if the spring in question is the balance spring. To overcome this problem, a ferrous component has been added to the alloy, which makes the spring more elastic.

The result is a spiral that is not completely antimagnetic, but still ten times less sensitive to magnetic fields than a conventional one, which does not absorb more energy than a traditional one, all being cheap enough to be mounted in Swatch System 51.

- Swatch System 51 are mechanical watches with automatic winding composed of only 51 parts against the 200 normally required for a traditional automatic, totally assembled by machine and sold to the public around 200€. Of course, the fact that the Swatch System 51 they are watches with a sealed case and that many internal components are made of plastic or welded, rather than metal and screwed, denies the same raison d'etre - perpetual maintenance - of a mechanical watch; however, the technologies introduced by this timepiece will also be used in conventional watches produced by other brands in the Swatch Group.

The spirals of the future

We can say that the balance wheel spirals, which have always been the subject of innovation and study, continue their race towards constant improvement. The materials, as is customary in the watchmaking sector, are always new, but one never forgets the projection towards the potential eternity that each mechanical watch must have within itself. For this reality like Rolex, Audemars Piguet and Swatch Group they continue to use technologies that can be reproduced in the future, such as those of metal alloys: unlike materials such as silicon, it will always be possible to build metal spare parts, and the clock can always remain in working order with the appropriate maintenance.