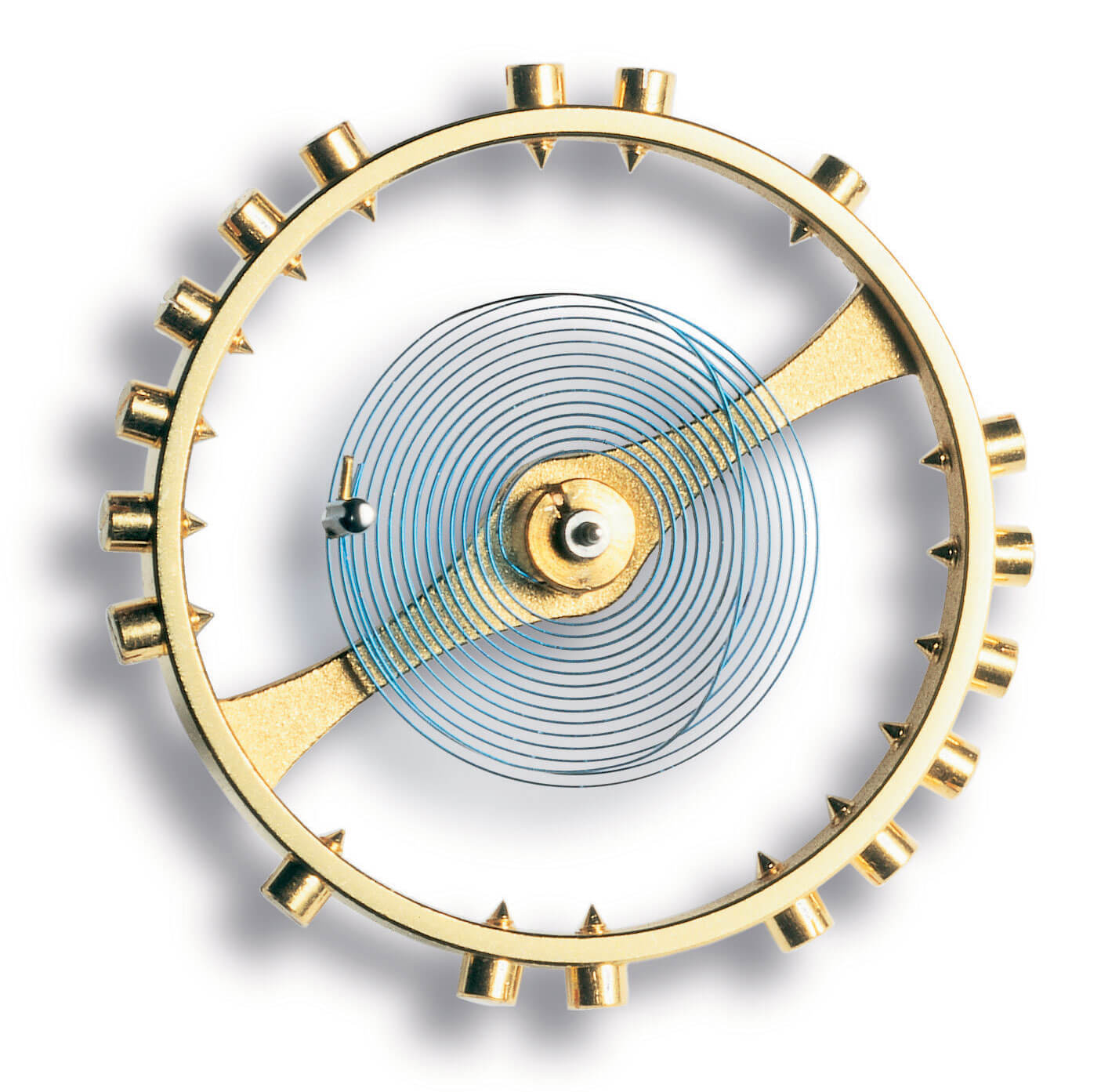

La spiral it is one of the most delicate and sensitive parts of a watch movement. It is a very thin metal sheet, with a diameter equal to about two thirds of that of the outrigger. Its function is to provide the return impulse to the balance wheel, which is pushed by the fork of the Swiss anchor, in turn set in motion by the escape wheel connected to the winding barrel.

La spiral it contracts and expands several times per second, and its thin coils are very close to each other. It is essential that they do not stick together, due to dirt or magnetization. The first problem is kept at bay by waterproof cases and the professionalism of the watchmaker, who always works in an environment free of impurities. The second, however, is difficult to resolve.

So let's see what solutions have been found for protect the spirals from magnetic fields.

Spiral magnetization and how to prevent it

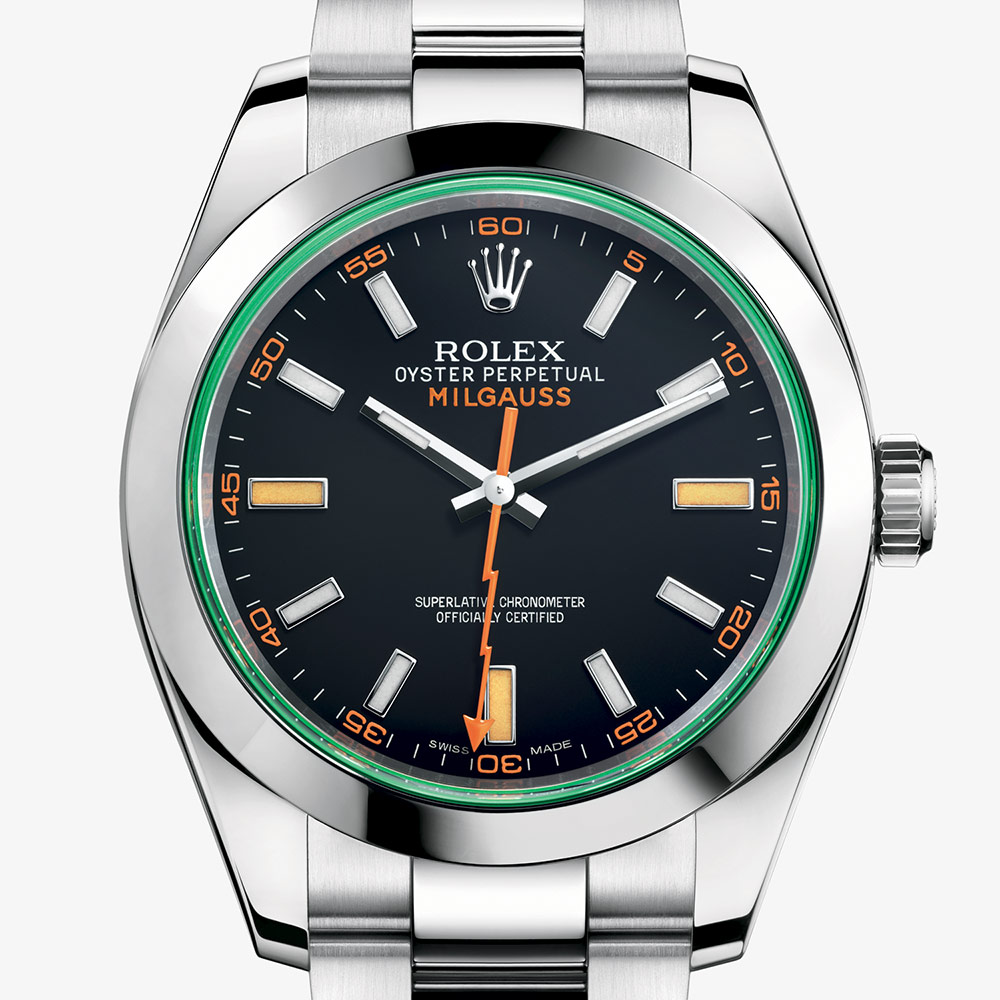

An internal soft iron outer casing is the simplest means of making watches and, in particular, their spirals, resistant to magnetic fields.. However, this solution involves an increase in the thickness of the case, which is therefore not always desirable, especially in watches that are already thick for construction reasons, such as automatic or divers.

The solution to the risk of magnetization of the balance spring can only be found in the way in which the balance is created. By choosing materials that are as little sensitive as possible to magnetic fields, you can limit the perniciousness of exposure to electromagnetic fields generated by computers, cell phones, household appliances, and any other object powered by electric current which, by its nature, emits magnetic fields.

The new materials

Finding the right material to make spirals that are not vulnerable to magnetic fields is not easy, however. The material of a spiral conventional is already in itself the result of careful research: the watch is subject to shocks, overturning, temperature variations that can affect the deformation of the metal of the hairspring, and watchmakers have gradually developed alloys suitable to withstand this type of threat . Any alteration to the alloy of which the spiral is made is extremely risky, because it involves the possibility of losing the skills already acquired with past experience.

Some manufacturers have chosen the path of new materials derived from the computer industry. We are talking about silicon spirals, adopted for example by Omega and Tudor. This material has the advantage of resisting, like a normal alloy for spirals, to all ordinary stresses: but not being a metal, it is indifferent to the presence of magnetic fields. This feature is called non-magnetic.

Il defect of the silicon spirals it is inherent in the characteristic that makes them valuable, namely that they are not made of metal. The silicon alloys do have mechanical qualities highly appreciated in watchmaking, but they are extremely fragile. It is not uncommon that during a revision a slightly incorrect movement of the watchmaker can reduce them to dust.

Another defect of silicon spirals, this time relevant for the future, is the uncertainty of the availability of these materials in the future. The industry that produces them, that of electronics, is in fact constantly updated, and in some sectors it is already thought of abandon the silicon in favor of more performing materials, such as carbon nanotubes. Given the nature of the mechanical watch, i.e. that of an object that can be maintained indefinitely over time, which in theory can always be repaired by a watchmaker skilled enough to make worn or broken pieces, it is clear that a problem arises. The silicon spiral, unlike those in metal alloy, cannot be produced by a craftsman: it requires an industrial apparatus specifically dedicated to the processing of silicon. When these materials are no longer economically attractive - and this could happen even in just a few decades - it will no longer be possible to repair mechanical watches that integrate silicon components.

Silicon spirals: what future?

Of course, in theory a watchmaker of the future could replace a damaged silicon hairspring with a metal alloy one, ensuring that it has the same period of oscillation as the one replaced; but in this case it would be a question of making a clock that is partly different from the initial one, not of maintaining an existing one by replacing its components with others that are perfectly identical to the original.

A final problem with silicon spirals is that we don't know how long they can last over decades and centuries. This material is so new that there are no reliable data on its mechanical qualities in the long run.

That's why, in the next article, we will go to the discovery of others technical solutions that Case like Rolex e Omega have recently introduced mechanical on their watches to make the hairspring increasingly resistant to stress.